A web app that empowers businesses to operate smarter, safer, and more efficiently.

“Spend Less, Earn More”

All businesses share the same ultimate goal — to spend less and earn more while maximizing profitability and efficiency. Yet achieving this balance is rarely simple. Rising costs, unexpected challenges, and outdated systems often stand in the way. That’s where thoughtful design and innovation come in. By deeply understanding user needs and aligning them with business objectives, I create solutions that don’t just look good but deliver real impact

Safe Sense is a smart web app that leverages IoT sensors to provide HVAC technicians and refrigeration users with real-time visibility into refrigeration performance. By delivering proactive alerts when temperatures rise or equipment shows early signs of failure, it helps prevent costly food waste, unexpected breakdowns, and safety risks. Designed with a user-centered approach, the app streamlines workflows, reduces decision fatigue, and empowers professionals to act before small issues escalate—ultimately protecting resources, boosting efficiency, and ensuring long-term reliability.

Team

Duration

Tools

Key Skills

Team of Six

130+ Hours

Figma, Figjam, Procreate, Photoshop, ChatGPT, and Slack

UX Research, Qualitative Interviews, Visual Design, Wireframing, Prototyping, User Testing

Self Reflection

This project is with WinWinLabs, a nonprofit organization, where I collaborate with a team of volunteers of developers, cybersecurity experts, and firmware and analytics engineers, guided by a Go-To-Market Strategist. Working with an actual cross-functional team allowed me to experience real-world collaboration, coordinate across different disciplines, and contribute to a project that balances technical feasibility with strategic goals.

Persona

-

The HVAC Technician

Age: 38Role: HVAC Technician

Industry: Commercial Refrigeration

Location: U.S., supports multiple retail and restaurant locations

-

This user is an experienced HVAC technician who relies on IoT-based tools to monitor and maintain refrigeration systems, including rooftop units and walk-in coolers. With multiple facilities under his care, he values smart systems that provide real-time data, mobile alerts, and easy access to historical trends. He’s tech-savvy and prefers tools that reduce manual checks and offer proactive maintenance insights.

-

Prevent refrigeration failures by detecting issues early.

Receive accurate, real-time alerts on his phone.

Use cloud dashboards to monitor multiple sites remotely.

Integrate IoT monitoring into his maintenance workflow for efficiency.

-

Delayed detection of coil freezing despite IoT tools.

Missed alerts due to poor cell reception or app crashes.

Inconsistent data logging when Wi-Fi is weak or offline.

Lack of predictive insights from current sensor tools.

-

A hybrid IoT system that tracks both ambient and coil temperatures.

Reliable mobile alerts with clear recommended actions.

Offline functionality that syncs when back online.

Smart dashboards with visual trends and downloadable reports.

Seamless integration with his existing maintenance software.

Users working in commercial facilities are under increasing pressure to maintain system efficiency while minimizing downtime, equipment failures, and food waste. However, current monitoring solutions often fall short due to delayed alerts, unreliable data logging, and limited visibility into coil performance. These gaps can lead to undetected coil icing, costly breakdowns, spoiled inventory, and unnecessary manual inspections.

Defined PROBLEM

Discovering the PROBLEM

Competitors

I analyzed competitors like Temp Stick, SensorPush, and Inkbird to understand the strengths, limitations, and user experience patterns of existing IoT monitoring solutions. This helped me see which features users find intuitive or frustrating, identify gaps in ambient and surface-level sensing, and uncover opportunities for differentiation. By grounding my design decisions in these insights, I was able to create a hybrid system that better supports early frost detection, energy optimization, and preventive maintenance—addressing real user needs more effectively.

By talking to real users, we built Safe Sense to address the challenges they face every day.

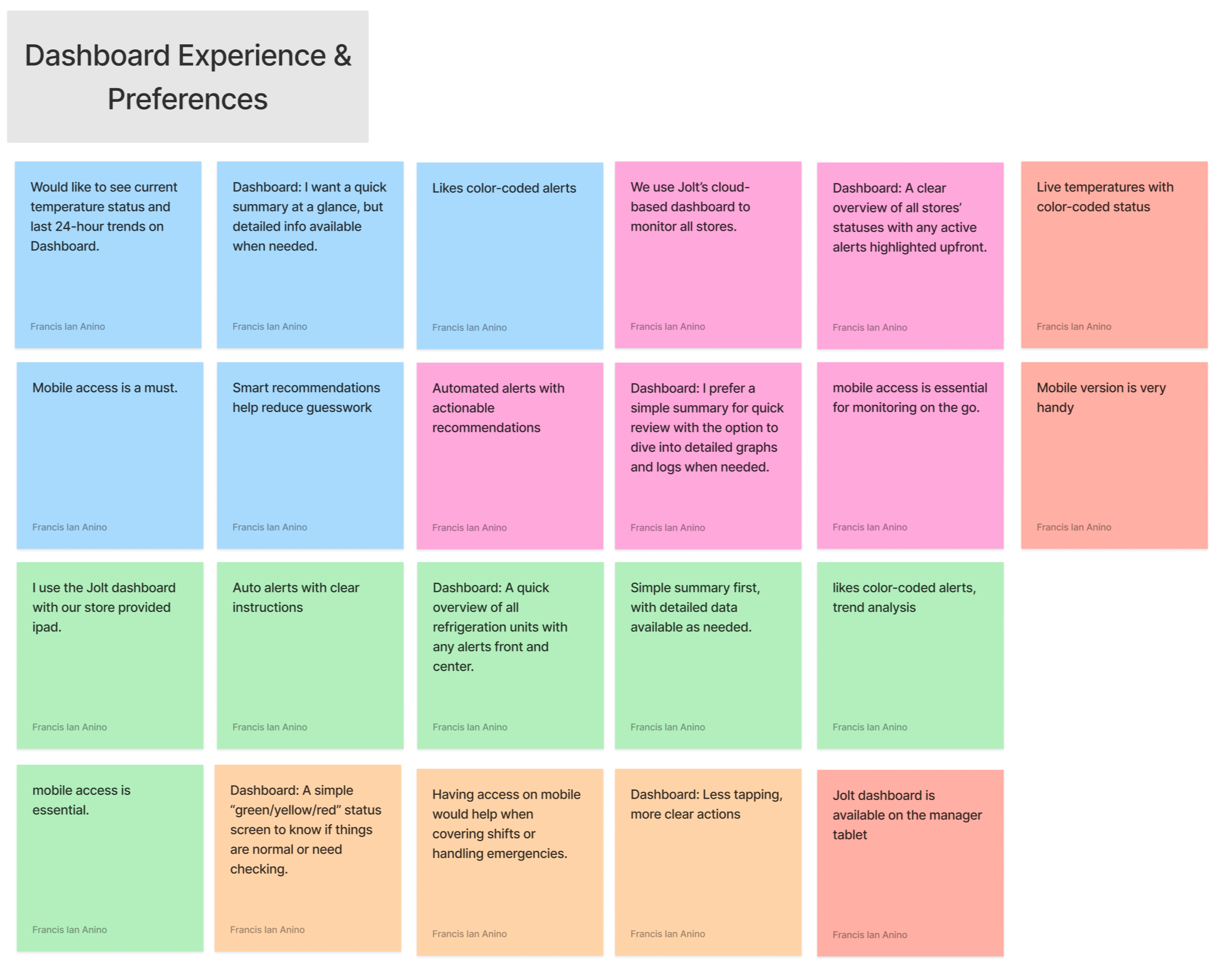

To understand how users monitor temperature and equipment performance, I interviewed an HVAC technician working at McDonald’s as well as four store managers, since they already use a temperature monitoring app in their daily operations. I explored their workflows, the tools they rely on, and the challenges they face in preventing equipment failures or product loss. These conversations revealed key pain points and opportunities to make monitoring smarter, alerts more actionable, and preventive maintenance easier.

Interview Insights

Users need a smarter, more dependable system that offers real-time tracking of both ambient and coil surface temperatures, proactive alerts, and good connectivity—empowering them to act before small issues become expensive problems.

How Safe Sense Solves the Problem

Designing the Solution

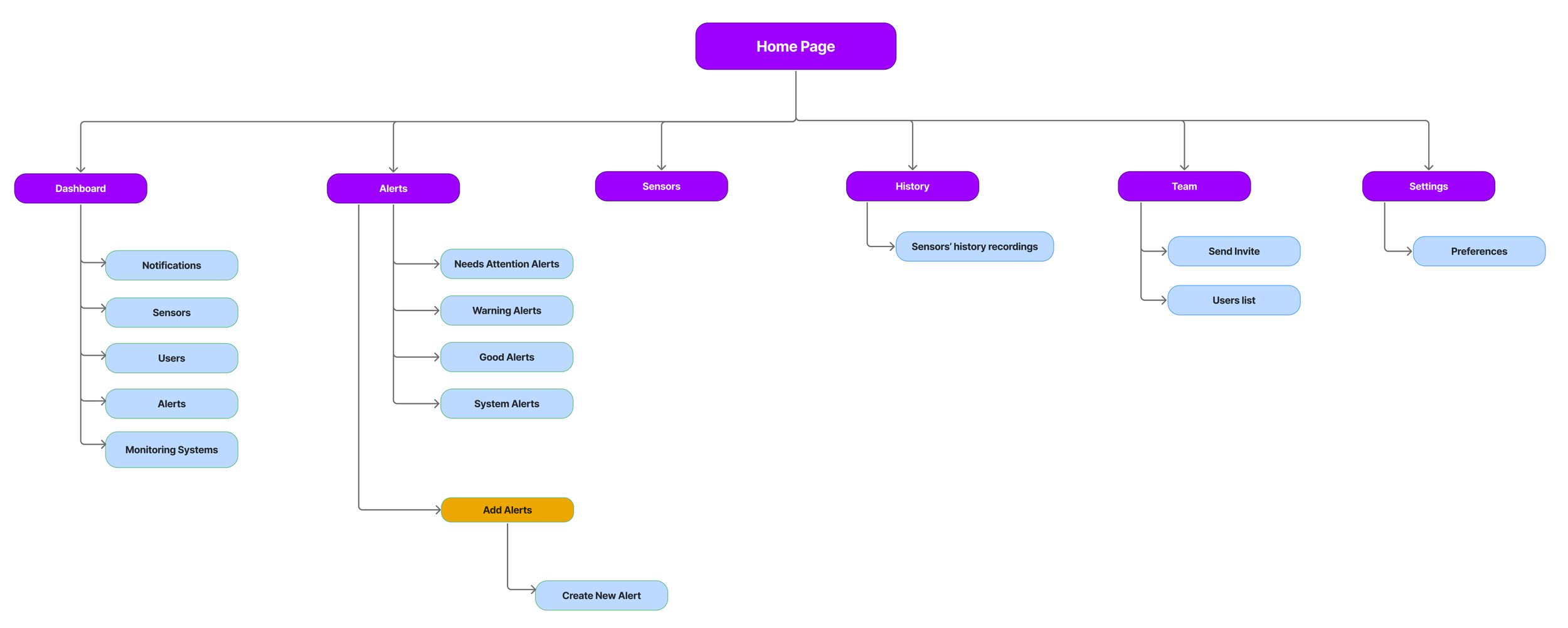

Sitemap

The Safe Sense sitemap is structured to give users streamlined access to critical monitoring features.

Dashboard- where real-time ambient and coil surface temperatures are displayed.

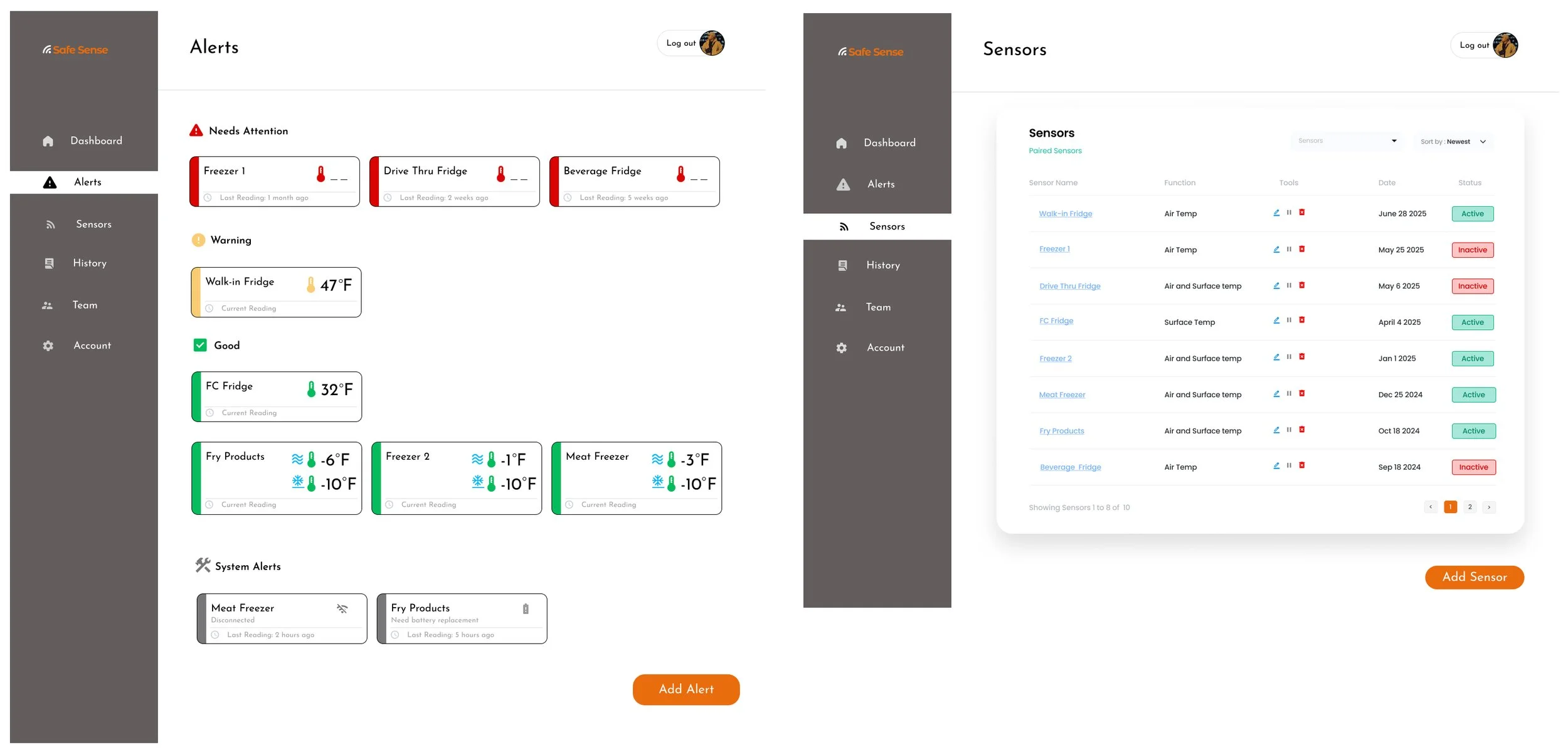

Alerts- provides a quick overview of all active alerts and allows users to create new ones for proactive monitoring.

Sensors- manages connected devices, giving users the ability to add, remove, and track sensor performance.

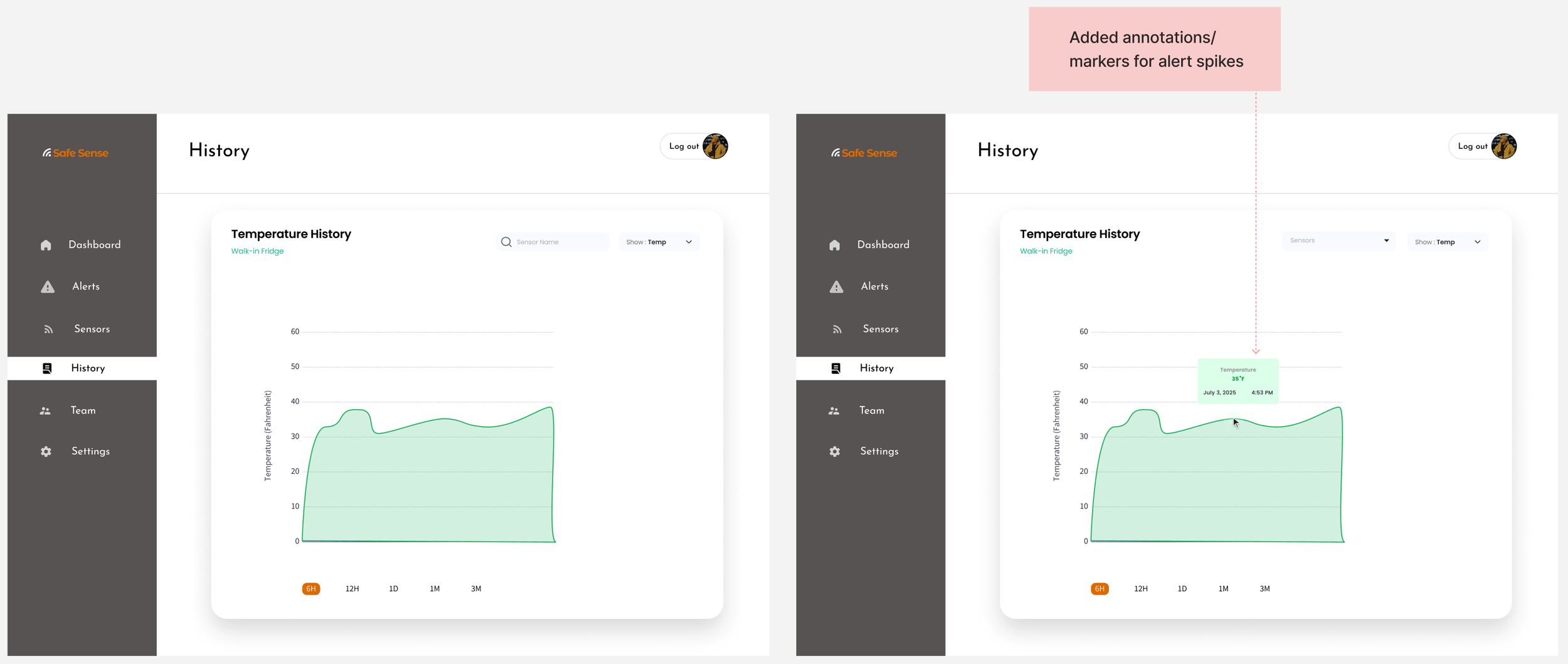

History- serves as a data hub, storing temperature logs for analysis and compliance. Team enables collaboration by letting users manage roles and permissions, while Settings allows customization of dashboard preferences and notification options.

This sitemap ensures a balance between clarity, control, and efficiency—empowering users to act quickly and confidently.

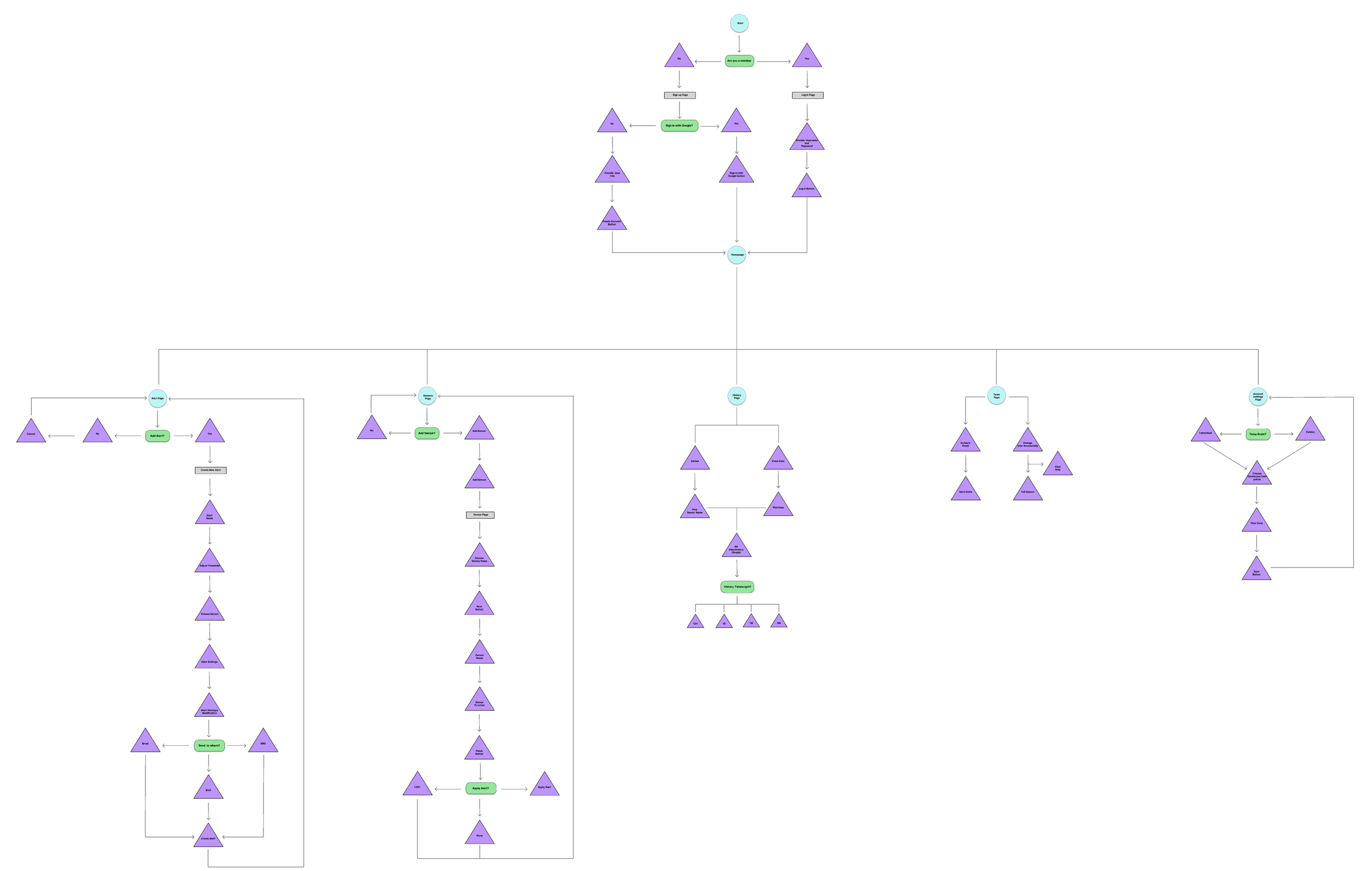

User Flow

In designing the Safe Sense user flow, I started by defining the entry point: the Login page. This ensured secure access and a smooth onboarding experience for users before reaching the core system. From there, I mapped the path to the Dashboard, the central hub for real-time monitoring. I prioritized making critical tasks—like checking alerts or managing sensors—accessible in just one or two steps. I then built supporting flows, including History for reviewing past data, Team for collaboration, and Settings for customization. Throughout the process, I focused on reducing friction, creating clear decision points, and iterating on the structure to ensure that users could move seamlessly from logging in to monitoring, managing, and resolving issues with confidence.

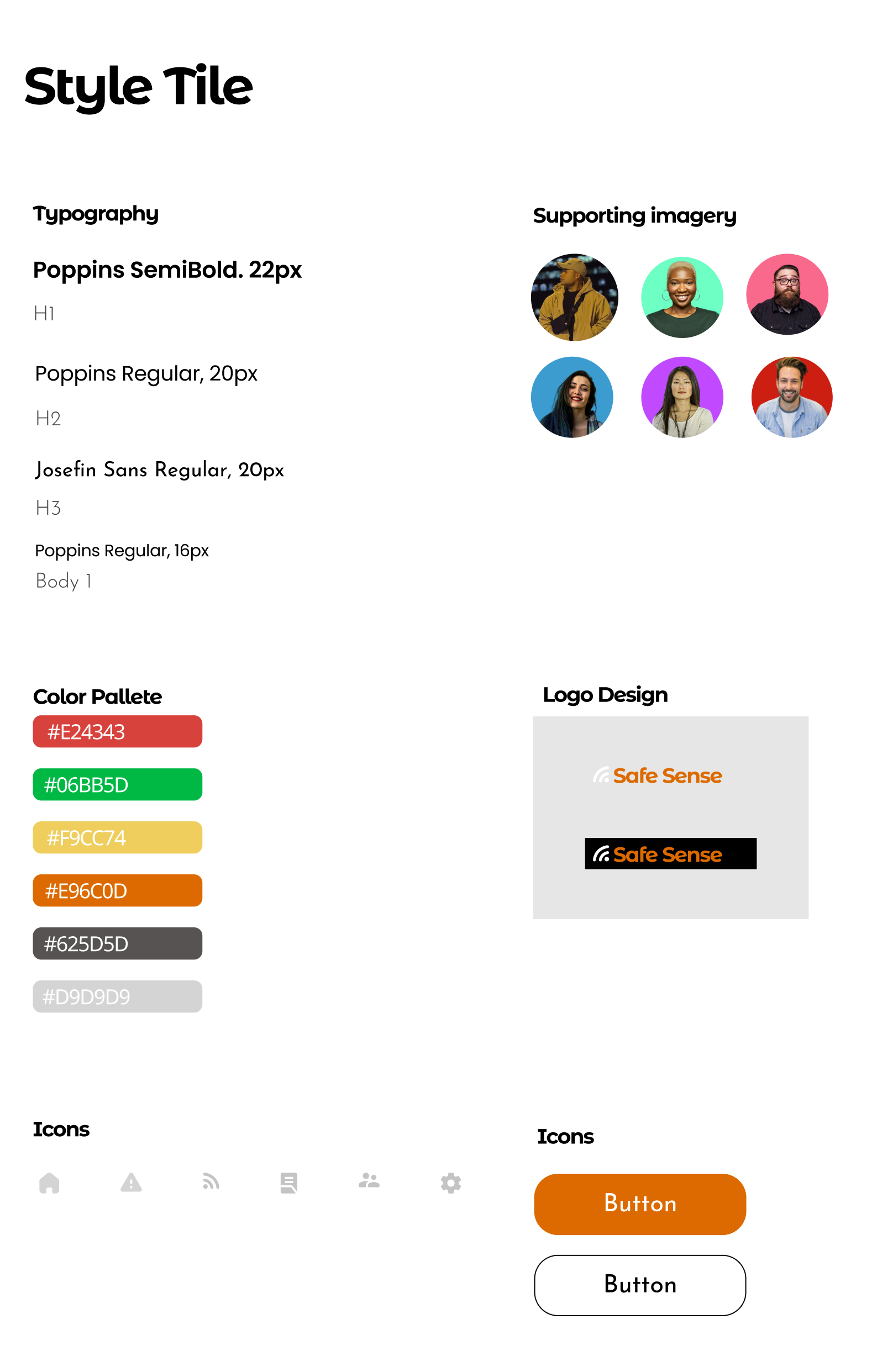

Branding

My design sketches evolving into digital screens

LoFi Wireframes

HiFi Wireframes

I kicked off the design process with hand sketches, letting ideas flow freely on paper as I explored layouts and user flows guided by the sitemap. Once the concepts felt right, I translated them into digital Lo-Fi wireframes, testing and iterating based on user feedback. This hands-on, iterative approach allowed me to catch issues early, refine interactions, and build a solid, user-centered foundation before diving into high-fidelity designs.

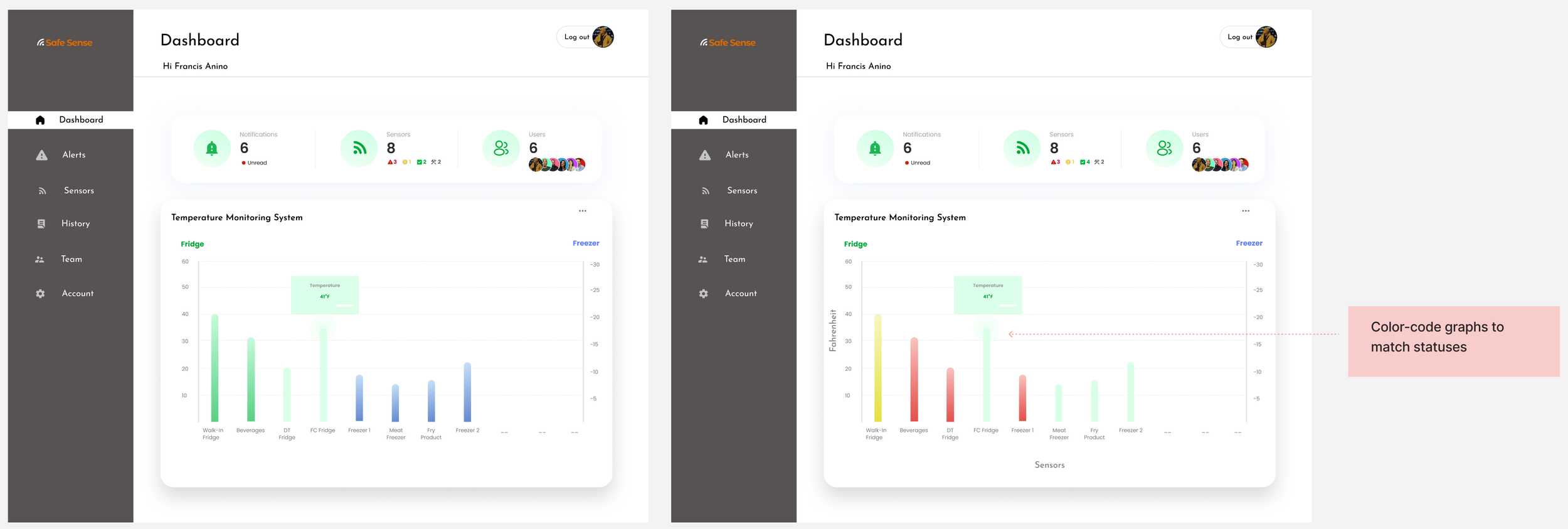

How My Screens Evolved

Built on validated Lo-Fi wireframes: Transformed tested concepts into high-fidelity designs.

Integrated branding & visual design: Applied color palette, typography, and UI patterns for a cohesive, engaging interface.

Iterated based on feedback: Refined layouts, interactions, and details to improve clarity, accessibility, and usability.

Usability Testing Result

The usability testing evaluated how effectively users interact with Safe Sense’s temperature monitoring system, uncovering strengths in accuracy and ease of use while identifying areas for improvement.

Iterations

More Usability Testing to Validate new iterations.

Conduct a pilot test at one of the leading fast food chains, McDonald’s.